Retail Inventory Management for Hard and Soft Goods: Challenges and Strategies

A retailer’s “brand” is defined by the types of goods it sells. A specialty retailer known for health and nutrition solutions will focus on long-life consumptive products like vitamins and supplements, while a fashion clothing merchant offers stylish apparel that has a short life and is replaced with something different on a regular basis. Each of these types of products has its own unique inventory management challenges. If your product strategy includes both types, you face some additional considerations:

- Your inventory management team should have broader forecasting knowledge and experience, and needs to understand which forecasting techniques best serve each product in the assortment

- The way you measure the profitability of inventory decisions is different for long-life vs. short-life items

- Long-life and short-life products compete for store space and budget dollars with very different objectives

Let’s take a closer look at these challenges and how you can deal with them. But first, it’s important to understand the factors that make these two types of products so different from an inventory management perspective.

Hard vs. Soft: What’s the difference?

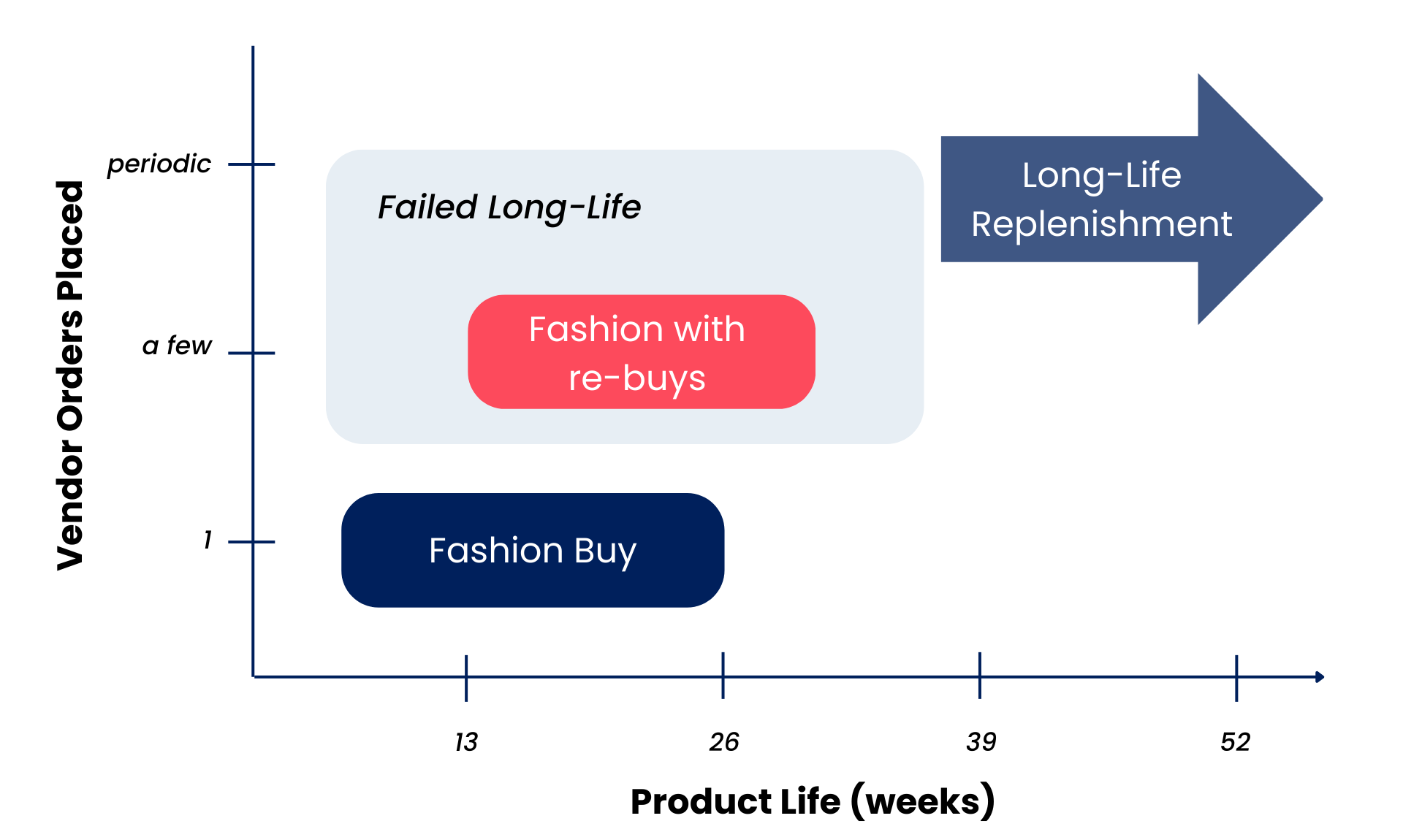

The terms “hard” and “soft” are often used to distinguish these two types of products, but from an inventory management perspective, what’s important is how long you intend to sell the product, and how many times you can reorder from your vendor.

The typical long-life replenishment item can be carried for a period of years. The retailer places frequent periodic orders for more units from the vendor.

In contrast, a classic fashion item is ordered from the vendor months in advance of the season in which it will sell and is only on the shelves for a limited time – as little as a month or as long as 6 months. Once the season starts, there is typically no option to order more – the retailer has placed a bet that a certain number of units can be sold in the allotted window of time. At the end of the season, the shelves must be cleared to make room for the next season’s assortment.

Given these very different characteristics, let’s look at the challenges facing a retailer that offers both types of products.

Forecasting: you’re going to need a bigger boat…

Forecast accuracy is typically much better for long-life items than it is for fashion items, for obvious reasons – you have a lot more history to go on and a more predictable seasonality, which lends itself to “lights out” automation. Short-life products turn over quickly and only a fraction of them return in subsequent years, so forecasting their demand has traditionally depended on merchant judgment to augment automated systems that use machine learning forecasting techniques.

These differences have led many retailers to assign these products to different inventory management silos. But the reality is, there is a lot of cross-over in forecasting techniques that can be applied by a team that is looking at the whole picture and can make intelligent tradeoffs.

For example, there are replenishment products that are on the shelves all year round, but which sell majority of their units in a handful of weeks during the holidays. These products can benefit from some of the forecasting techniques used for seasonal items when their peak selling period approaches. By the same token, other items may start out as fashion buys, but then transition to long-life replenishment. Managing that move effectively depends on a seamless shift in the forecasting process.

With different teams managing the forecasting in these situations, there is a greater likelihood of failing to use the best forecasting approach demanded by circumstances.

Maximizing profitability requires different methodologies

Short and long-life products have very different inventory management costs. For long-life products, the management costs are the ongoing carrying cost of the inventory held in stores on the one hand, and lost margin incurred when demand exceeds available store inventory on the other. Your replenishment system should be designed to find the “sweet spot” that minimizes the sum of those two costs.

For short-life products, the profit-optimal goal is to maximize the full-retail sell-through of the inventory purchased from the vendor. That is to say, you want to sell as many of the units you bought at as close to your original target retail price as possible. To do that, you must accurately determine the right number of units to buy, the best timing and placement of store allocations, and the optimal timing and depth of markdowns as the season progresses. This is best achieved with an integrated system that coordinates the buy, allocation, and markdown decisions to arrive at the most profitable solution.

The important thing is this: when measuring the profitability of your business, you should apply a different yardstick to your short and long-life products.

Competing for Space & Dollars

In reality, most retailers have a mix of short and long-life products, but the proportions vary based on the focus of the business. A fashion retailer will skew heavily towards short-life items, but will often sell some long-life products that complement the fashion assortment and provide a more predictable revenue stream. Similarly, a business that is predominantly long-life products will also sell some fashion items to boost visual interest and foot traffic.

These two types of products are often managed by separate groups that know how to maximize the profitability of their respective assortments. But this separation of responsibilities can lead to problems when teams start competing for floor space and purchasing dollars. Rather than looking at maximizing overall profitability, preference is often given to the type of merchandise that is predominant in the business, while the other is relegated to a “supporting” role whose profitability is not considered as important.

For this reason, it’s important for the management team to have a shared profitability goal, and work together to find the right stocking level for every product, whether it is short or long life.

Summary

If you have both short and long-life products in your portfolio, you might want to review your management practices with respect to forecasting, profitability measurement, and assortment prioritization. Even identifying a few simple changes in your processes could yield significant financial benefits. Interested in profit-optimizing your inventory? Contact our retail expert team today and we’ll discuss how we can help you maximize your inventory efficiency.