How to Reduce Fresh Waste by Using AI-Powered Demand Forecasting and Replenishment

When the global pandemic first began, and some rushed to the grocery stores to stockpile, others hit the keyboards. Worldwide Google searches for “online grocery shopping” and “fresh food delivery” reached all-time highs in April 2020.

It’s no surprise that consumers also changed their consumption habits during that time and shifted their priorities when it came to fresh food. As many people continue to work from home and because fresh food is seen as a driver of health and wellbeing, fresh fruits, vegetables, and dairy products consumption increased.

The challenge of fresh food waste

Online grocery shopping, more fresh food consumption might be the new norm in the wake of the Covid-19, but reducing the fresh food waste will continue to be a challenge for grocery retailers.

In recent research conducted by U.S. Food & Drug Administration (FDA), it was found that, In the United States, between 30-40 percent of the food produced is wasted. The U.S. Department of Agriculture (USDA) estimates the value of food loss and waste for retailers and consumers each year to be over $161 billion. These alarming numbers have increased in recent years as retailers have been slow to adopt new digital solutions that allow better matching of supply and demand for robust waste management.

Fresh food waste is a significant problem, and it is forcing a restart

The world’s fresh food waste problem is bigger than we thought. FDA research only magnifies the importance and urgency of this problem. And financially, wasted fresh food equals money in the trash. According to Refed, a non-profit organization dedicated to fighting food waste in the U.S., food waste costs retailers about $18.2 billion a year. That’s a lot of money left on the shelves and a lot of food left in the trash. So, it’s no longer feasible for grocery retailers to write off fresh food losses simply a ‘reoccurring cost’.

Today, grocers need to take bold steps to address these issues and find new ways to prevent fresh food waste in the first place. They need to re-examine their inventory planning strategies and see how they can maximize profit margins and reduce waste without sacrificing quality or customer value. It is an opportune time for them to go back to the drawing board on their supply chains and take a closer look at how they can enhance their demand forecasting and replenishment capabilities.

How to tackle the problem of food waste

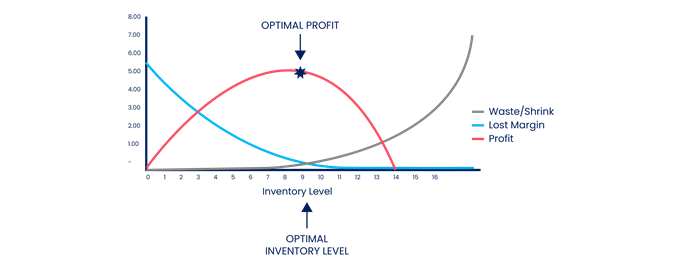

When placing orders with fresh-food suppliers, retailers must constantly make difficult trade-offs. If they order too much, it will go to waste, and waste will quickly eat into already thin margins. On the other hand, if they order too little, there will be a risk of lost sales, lost customer loyalty.

And the problem is, traditional inventory planning systems taking a fixed, rule-based approach to demand forecasting and replenishment no longer work well with fresh food. That’s because fresh is complicated. It’s like a complex supply chain puzzle to solve. The item conditions change from day to day. Berries go bad, bananas and avocados age…

There are also local events, local demand, promotions, regional customer preferences, weather – so many things to take into account. The good news is, there is a new way, a better way to deal with these issues:

Enhance demand forecasting capabilities to lower the risk of overstocking

As grocery retailers look to efficiently position inventory in their supply chain to minimize waste, there is a need to understand that this all starts with accurate and robust demand forecasting. The more precise the forecast, the lower the risk of overstocking. The better the forecast, the higher the financial benefit.

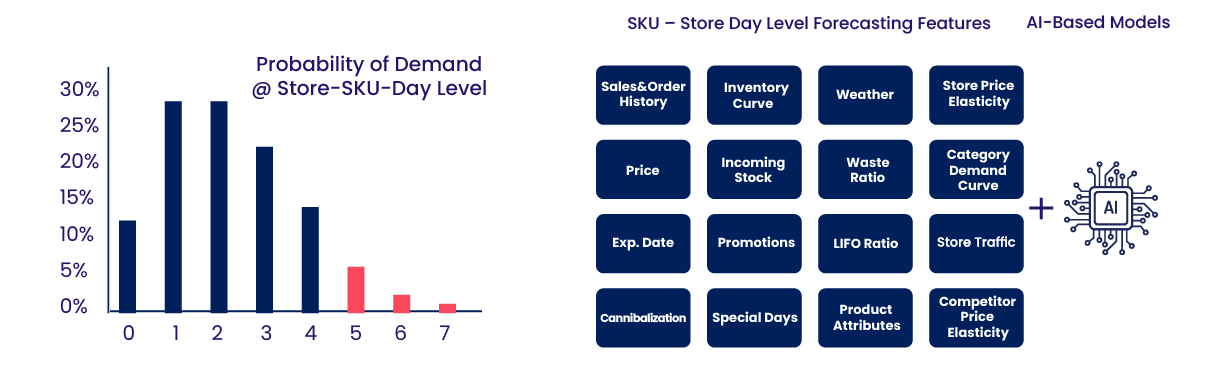

As the complexity of planning increases, advanced analytic techniques and explainable AI is the only way for grocers to generate highly accurate forecasts -and the only way to determine optimal stock levels.

And potential rewards of robust and detailed forecasts are endless – grocers can make more intelligent, data-driven, right-time decisions that maximize profitability, reduce waste at stores while fulfilling environmental responsibilities.

Optimize fresh food replenishment decisions

Old-fashioned replenishment systems with service-level frameworks fail at managing the fast-changing world of fresh products. Due to the variability of local demand based on events, changing trends and tastes, weather, as well as price changes and promotions, can make grocers’ job a lot harder. Plus, the constant substitution and cannibalization across categories can be very challenging.

In this environment, modern replenishment solutions taking advantage of AI-powered demand forecasting, demand sensing and probabilistic forecasting capabilities can help grocers to optimize their fresh food replenishment decisions.

Optimized inventory decisions balance the cost of wastage versus the cost of lost margin dollars for every product at each store for each day and ship the optimal amount of product to stores given the replenishment schedule over the week and the anticipated demand for the upcoming few days.

With accurate probabilistic forecasts, it is possible to characterize the risk of spoilage versus the risk of a stockout (lost margin) for each case pack of a product that will be shipped to a store. That, in turn, gives us optimal inventory ordering decisions. A simple interpretation of the algorithm corresponds to the one rule that matters “send every case pack to the store that maximizes overall net profit margin of the product.”

The profit-optimization logic based on probabilistic forecasting also helps retailers allocate across stores optimally when available inventory is limited either at DC’s or from the vendor – making sure that product flows every day to the locations that will have the maximum sales potential (demand) and minimum chance of going to waste.

How Invent Analytics can help

The question today is how can grocers make fresh food less wasteful, more efficient, and profitable? By upgrading inventory decisions from a judgment-driven, KPI-measured process to a financial optimization-driven and measured processes, grocers can ensure rapid replenishment cycles and higher customer service levels.

Invent Analytics’ Store and DC Replenishment give grocers what they need to compete in a rapidly changing environment and turns food waste from a costly burden into a valuable profit resource.

The sophisticated solution helps to achieve better inventory planning at the store level by using real-time online orders. It balances lost margin from out-of-stocks and the cost of carrying inventory. In addition, it determines the optimal reorder points and order quantities by taking into account the fresh product profitability, changing demand patterns, and weather.

As a result, grocers can make profit-optimized inventory decisions every day. And deliver superior customer service while increasing the profit margin for the business.

Interested in reducing waste, optimizing inventory while boosting profitability? If so, get in touch with our team of experts today to find out how Demand Forecasting, Store and DC Replenishment can help you achieve your goals.

Download our free pocket guide Earth Day 2022: How to Reduce Fresh Food Waste to find out how retailers can tackle the problem of food waste using AI-powered demand forecasting and replenishment.