How to Optimize Inventory Using Analytics-Driven Supply Chain Improvements

Inventory optimization is a critical part of an efficient supply chain. When done right, it contributes significantly to the success of any retail business. So, now more than ever, retail supply chain leaders are aiming to meet their omni-channel customer demand and gain a competitive advantage. To achieve these goals, they are focusing on enhancing their demand forecasting, allocation, and replenishment capabilities.

To deal with tens of thousands of SKUs across various channels and manage inventory successfully, retailers need AI-driven, omni-capable inventory optimization tools that can reduce costs and boost profits.

In this article, we outline how next-level AI-based profit-optimization models and analytics-driven supply chain improvements can empower retailers to upgrade their inventory management capabilities. We also share 8 effective ways they can use to optimize inventory and make their operations more responsive, efficient, and integrated.

1. Move from a service-level-driven model to a profit-optimization model

To keep up with the evolving retail landscape and boost profits, retailers have no choice but to reimagine, streamline and simplify complex inventory planning processes.

After all, it’s every retailers’ dream to have the right amount of inventory at the right place at the right time without having excessive inventory or losing sales. To achieve that, retailers need to take advantage of adaptive, smart analytics and explainable AI models. They need to move from a traditional service level approach and upgrade their inventory decisions from a judgment-driven, KPI-measured process to a financial-optimization model.

Using sophisticated models such as AI-powered profit optimization, retailers can increase stock availability, reduce inventory holding cost and don’t have to choose between profitability and customer satisfaction.

2. Embrace an omni-channel sales and inventory optimization approach

In the traditional location-dependent inventory systems, every demand could be served and fulfilled by only one specific location. And this came with various operational costs and inefficiency.

To survive and thrive in the new era of omni-channel retailing, retailers need to embed omni-channel in the overall sales and inventory optimization strategies. They should have a responsive, unified supply chain structure to fulfill the demand from the best possible location at the right time.

3. Leverage advanced analytics and create a regular test and improvement cycle

With retailers under pressure to demonstrate growth in sales and profits, they introduce new products frequently. However, there might be some product types for every retailer that should be abandoned completely. Here, SKU rationalization comes into play and becomes a key in the lifecycle of a retailer.

Retailers leveraging advanced analytical-based tools can determine these products at a company level by considering various metrics and the competition. To minimize the potential loss of market share and profits, they can pinpoint the product substitutes, examine each product’s cannibalization effect, and make the right inventory decisions such as product positioning.

4. Analyze and test a store-based variety

Variety, assortment, and inventory availability are the cornerstones of the merchandise planning process. To stay relevant, increase sales and reduce excess inventory, retailers need to review their assortment plans and measure their plans’ efficiency in financial and operational dimensions.

The good thing is that retailers establishing the right partnership models can create store-specific metrics aligned with the company strategy. They can test several scenarios using AI-based models, successfully make profit-optimal inventory decisions and increase profits.

5. Determine the minimum visual quantities

One of the most common and effective ways for retailers to optimize inventory is by making extensive analysis to determine the minimum visual quantities for a specific product or product group. This way, they can increase sales of these products in different stores by eliminating the probability of falling short of inventory. In addition, by taking advantage of continuous tests and reviews with analytical tools, they can also avoid having excessive inventory.

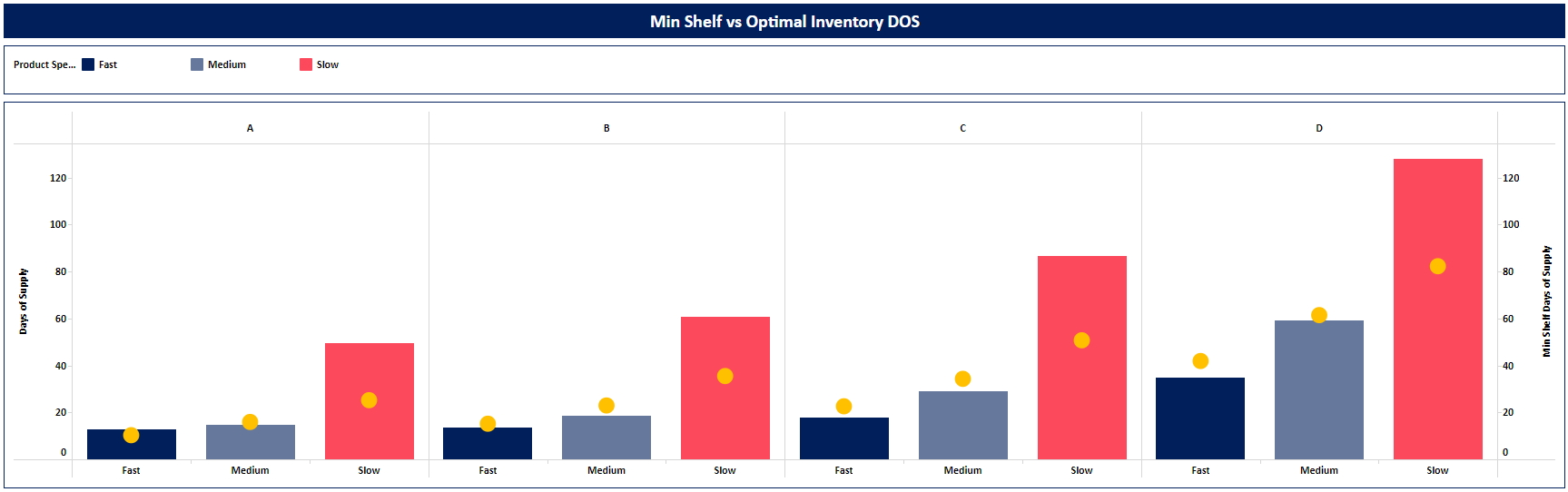

For example, the graphic below shows that fast seller products cause more stock holding than the optimal point in the not-so-fast seller stores due to the minimum visual constraint. (See column C – the fast area).

The illustration suggests focusing on these SKUs and drill down into the locations to recover from the profit losses.

6. Identify unproductive inventory and make lost sales cross-comparisons

Mastering inventory optimization requires analyzing the inventory movements, non-selling item location pairs, and out-of-stock selling item locations.

To identify improvement areas and develop effective strategies for assortment and allocation decisions, retailers need to leverage future-fit inventory optimization solutions such as Omni-Plan. This way, they can have a clear picture of improving future planning decisions and reducing inventory.

7. Reduce lead times and review times and effectively handle volatility

It’s true that while retailers adjust their operations to improve margins, they should also prioritize a high level of customer service. Why? Because today customers can choose not just where to buy, but also where to collect or receive their orders. They can also choose how fast they want their orders to be fulfilled.

In fact, according to Gartner, as fulfillment models expand, control of inventory will be a vital factor in ensuring customer loyalty and retention. However, long lead times can be a huge pain point to ensure customer satisfaction. The consequences of extended lead times can go far beyond a simple annoyance and become very costly. There is also the risk of running out of inventory or carrying more.

On the other hand, the main challenge for retailers today is to efficiently manage increased supply chain volatility. Of course, volatility has always played a crucial role in retail supply chains, but now retailers are still dealing with the pandemic and supply chain disruptions. On top of that, they are also aiming to have an effective supply chain network structure and inventory positioning strategy to fulfill their customers’ orders on time at a low cost.

Building strong partnership models with future-ready omni-channel demand forecasting and replenishment solution providers such as Invent Analytics may be the greatest factor in reducing lead and review times. Retailers can also handle Covid-like high volatility environments effectively.

Using what-if scenarios and decision support tools, they can reduce costs and overcome operational difficulties and supply chain constraints that cause headaches. And by taking advantage of strong partnership models, they can continuously test, learn, and get better.

8. Review case packs and their financial impact in different sales periods

Case pack quantities come with the supplier packings, and they are often perceived as unbreakable quantity packs. However, there’s an opportunity in breaking down these case packs to avoid inventory accumulation in various locations. Retailers using scenario testing tools can easily identify these opportunities and turn this meaningful data into profitable inventory decisions.

How Invent Analytics Can Help You to Profit-Optimize Inventory

At Invent Analytics, we help retailers profit-optimize their supply chain planning and deliver significant financial improvement with our AI-powered, omni-channel inventory and price optimization solutions. By making every inventory decision based on highly accurate granular forecasts, we help them to optimize inventory and maximize profitability.

Over 30 retailers worldwide work with Invent Analytics to accelerate their omni-aware demand forecasting, allocation, replenishment, and markdown capabilities. By taking advantage of Invent Analytics’ financial profit-optimization model and AI-based advanced analytics, they stay ahead of the competition.

If you’re interested in profit-optimizing your inventory, reach out to our retail expert team and discuss your inventory management needs today. See how a true partnership can help you strive for further inventory efficiency and grow profitably in the omni-channel era.