Retailers, Are You Ready for Allocation Challenges This Christmas?

This article was originally published in RIS News.

Christmas is just around the corner. It is said to be the most wonderful time of the year. But headlines over the past few weeks about global supply chain woes are making it difficult for retailers to get ready for a joyful holiday season.

This year the supply chain bottlenecks have become one of the biggest challenges retailers face. The expectation that everything will be readily available for this holiday has now become an unrealistic Christmas wish. Instead, there will be empty shelves and inventory shortages even though demand is already high, which is enough to make a perfect storm for retailers.

Successful inventory management and allocation is becoming the key focus for this holiday season as shortages are pushing retailers to put supply chain and planning in the spotlight. Retailers are trying to figure out how to optimize their inventory in the best way possible to make the most of Christmas in 2021. Today the question of what product, how much of the limited inventory will be placed in what store is on every retailer’s agenda.

Dealing with inventory shortages

How can retailers fulfill orders in an efficient and timely manner when they don’t have enough inventory on hand to meet the increasing demand?

The answer lies in agility – in mindset, technology, operations, and algorithms.

Retailers need to be agile and level up their planning capabilities to quickly respond to the sudden changes in the supply chain. And the first step to moving forward is all about getting allocation right.

Can your allocation fulfill consumers’ holiday wishes?

Allocating limited inventory for fast-moving items is relatively easier than slow-moving items. But slow-moving inventory allocation is particularly challenging. Think about an ugly Christmas sweater, for example. We know that the demand for this product is not as high as Christmas ornaments. But Ryan Reynolds, Hugh Jackman, and Jake Gyllenhall made these sweaters already popular, so they need to take their places on the shelves anyway.

Considering the inventory shortages this year, retailers can’t afford using old-fashioned forecasting and allocation models. Traditional allocation optimization models are no longer enough to get the right amount of the right products in the right locations. And one of the main reasons is that these models with rule-based approaches require more manual intervention by planners and lead to significant problems such as sending these ugly Christmas sweaters to the wrong stores where demand is not that high.

In the eye of the storm, retailers need to look for new optimization models that can get lower-velocity items such to highest-margin stores where demand is higher. They can take advantage of the probabilistic demand forecasting capabilities, easily optimize the placement of the products within their supply chain and put their customers’ favorite Christmas items close to them. Therefore, they can also reduce the risk of losing the sale.

How good is your allocation system?

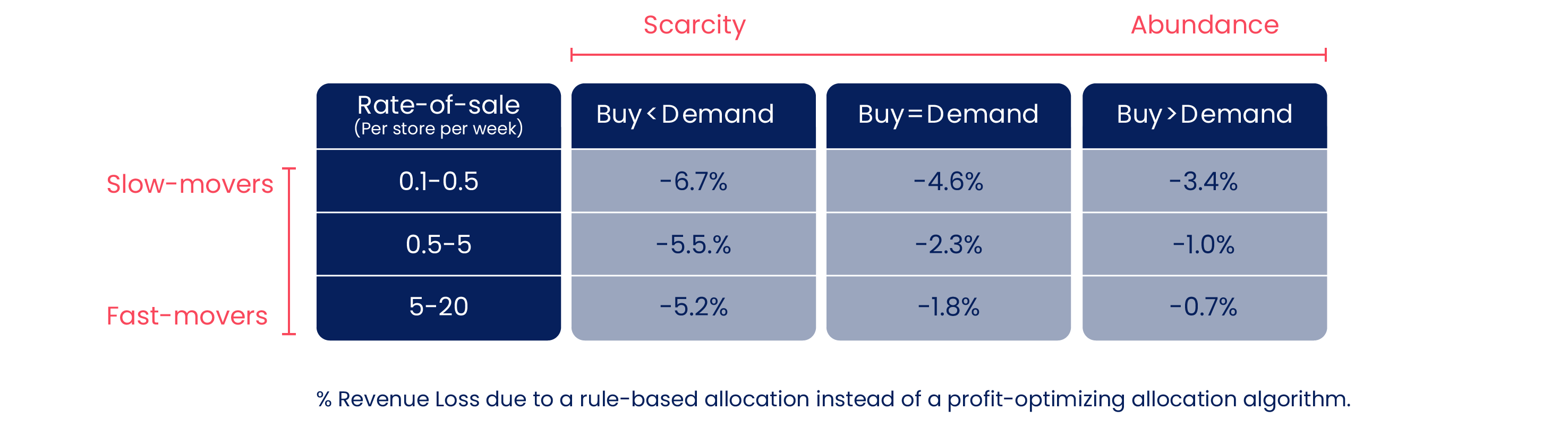

Using our advanced forecasting and simulation engines with client data from previous years, we compared the performance of simple rule-based allocation engines with a profit-optimized allocation system with granular forward forecasts at a store-SKU level. We find that the revenue loss due to rule-based allocation can be as high as 7% when inventory is scarce, and product rate-of-sale at store level is lower.

Most retailers assume they sell out everything when inventory is scarce, and therefore, allocation is less important. But our detailed simulations show otherwise. Suboptimal planning damage on customer satisfaction and revenue loss is actually most severe when inventory is scarce and the season is short -just like Christmas 2021. So, what now?

Using sophisticated allocation to make better Christmas planning decisions

The inventory shortages and supply chain constraints will be with us for some time. This situation makes it even more critical for retailers to revisit their planning strategies to make sure they can deal with what comes next.

At Invent Analytics, we believe retailers need to have a plan to succeed in such a disruptive environment. They also need revolutionized systems that calculate expected lost sales for any decision-making process and minimize the probability of losing a sale.

Benefiting from robust, allocation-specific forecasts, computing expected benefit probability for every unit allocation and sending the right amount of inventory to the right stores can help them achieve just that. Our Allocation Optimization Solution using demand probability with the highest predicted value for each and every potential item allocation helps retailers make better holiday season planning decisions. As a result of the dynamic and smart positioning of the limited inventory, retailers can get higher sell-through and become more profitable.

It’s time to make a wish list

The countdown for Christmas has begun. It’s time for retailers to make a wish list. This holiday season is filled with constant shifts and disruptions. And there has never been a better time to ask for a winning inventory planning solution to address today’s supply-constrained supply chains, evolve their planning functions, and get ready to make profit-optimized decisions every day. And luckily, we know how exactly retailers can achieve that.

Interested to know how you can strengthen your inventory planning capabilities? Have a look at our Omni-Plan here.

Did you enjoy reading this? You might also be interested in reading Inventory Shortages 4 Tips for Retailers