Recession or Not - Retailers Need to Be Ready

Welcome back to our new blog series: Innovate with Invent!

Have you been tuning in for our monthly huddles on LinkedIn? On the first Thursday of each month, I host a live chat where retailers gather and explore what's hot in the industry and what's on every retailer’s mind.

After each session, I recap the highlights here on our blog. In our last installment, we covered how economic challenges can impact inventory strategies. Now, we’ll look a little deeper into how retailers can take control amid all this economic uncertainty.

Let’s dive in!

Staying prepared for economic changes

It seems like you can’t turn on the news these days without hearing recession talk. And there are conflicting opinions everywhere. Some sources promise you that a recession will start in the third quarter of 2023. Some say early 2024. Others reassure you that the U.S. economy will prove to be resilient. Through all confusion and uncertainty, one thing is certain: whether a recession is coming or not, your retail business needs to be prepared.

What’s the best way to prepare when macroeconomic factors are so far out of your control? By focusing on the most important area you can control. For retailers, that’s inventory.

If you’ve joined any of my previous huddles, you’ve heard me say it again and again—inventory is everything in retail. If retailers don’t manage inventory properly, the effects can be catastrophic for business, regardless of economic conditions. And with the looming fear of a recession, anyone that works in inventory planning is now under more pressure than ever to maximize profit margins.

The good news? Retailers can boost profitability by taking a smarter approach to managing their inventory. Supply chain and inventory teams should begin by asking themselves three big questions:

How can we make the most of our existing inventory?

To give inventory the best chance to sell, retailers need to position each piece in the right place, at the right time. This means anticipating when, where, and how much customers will want to buy. After all, no one wants to lose a sale due to an out-of-stock product.

However, omni-channel buying has made everything more complex, and retailers need to get more strategic about how they position inventory across their supply chain. This could mean holding inventory back at the distribution center longer. Or it could mean shipping products to the store based on shorter demand signals. Sometimes, the best option may be keeping inventory available for online orders. Overall, the goal is to ensure inventory is available through whatever means the omni-channel customer will want to buy it.

How can we react quickly to changing customer demands and behaviors?

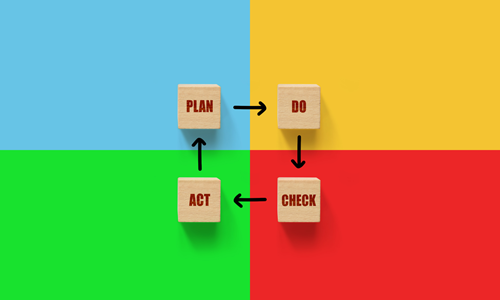

Omni-channel customer demands and behaviors are constantly changing. To stay ahead, retailers need to be proactive with their planning processes. Unfortunately, most retailers use traditional planning methods that leave inventory teams stuck playing catch-up.

Their planning teams start off by manually inputting values into their allocation or replenishment systems. These could be targets like service levels or days of supply. They let things run to see what happens, doing all the analysis in retrospect. How many out-of-stocks occurred? How accurate was our forecast? Planners then make adjustments based on these outcomes. They wait. They watch. Then they do it all over again hoping for better results. It’s all just a guessing game.

Instead, planners need the right answers in advance. Retailers should equip their planning teams with the tools to proactively determine where inventory will be the most profitable—while taking hundreds of variables into account. This kind of system can really be a game changer for planners. It removes the guesswork, the waiting, and the stress from anticipating changing customer demands.

What can we do to make an impact right now?

Given all the economic uncertainty, retailers should avoid getting into massive, multiyear infrastructure overhaul projects. Instead, they can see results right now by focusing on optimizing their existing systems with automation and AI technologies. By doing so, retailers can bring all their data and success metrics together for a clear picture of the most profitable inventory decisions.

Recession or not, there will always be challenges ahead. There’s no better time than now for retailers to get their supply chain and inventory processes ready for the future.

Thanks for joining me for this installment of Innovate with Invent, and be sure to tune into our next huddle session. Until then, keep on innovating!

Check out the full recording of our huddle on this topic here.