Fighting Phantom Inventory with AI

Thanks for checking out the latest installment of our Innovate with Invent blog series!

Once a month, Invent Analytics hosts an “Innovate with Invent” live huddle session on our LinkedIn page. We chat about retail trends and inventory challenges, then we recap the highlights here in a blog post.

In our last post, our VP of Strategic Accounts, Jonathan Alves, explored how retailers can turn demand forecasts into profit-optimized decisions. This time, I’ll dig into phantom inventory and how AI is helping retailers tackle the problem.

Phantom Inventory: Causes, consequences, and what retailers can do about it

In retail, it’s a fact of life that products don’t always sell as predicted. Consumer demand can change fast, and some items you thought would fly off the shelves wind up sitting around unsold.

However, lack of sales doesn’t always mean lack of customer interest. Sometimes, products may not be selling because they’re not actually in stock — although your inventory system says otherwise. This is what’s known as “phantom inventory.” These items are not physically available on the shelf for customers to find, and they may not even be in the store at all!

While every retailer is aware of the phantom inventory problem, it happens much more frequently and causes much bigger losses than most think.

What causes phantom inventory?

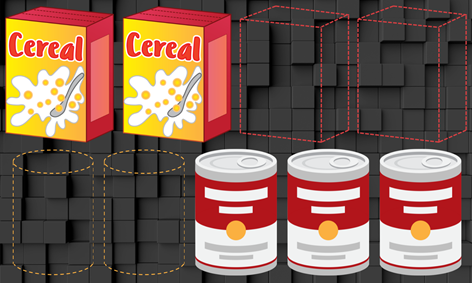

Phantom inventory is usually stems from simple issues like:

- Manual data entry errors: Employees accidentally enter incorrect data when they receive new inventory

- Inaccurate product placement: Products end up in the wrong place due to employees making stocking errors or shoppers putting unwanted products back on the wrong shelf

- Display errors: Products meant to be sold individually get left in case packaging, which discourages customers who only want to buy one or two pieces

- Theft: Retail theft is a growing problem, and stolen items may go undetected

- Visibility issues: Items may get pushed to the back of a top shelf or fall from their pegs. Customers can’t buy what they can’t see.

- Excess inventory left in the stockroom: Stores take inventory that won’t fit on the shelf and store it in the stockroom. But they may forget to pull out that inventory when the shelf gets empty.

While most of these issues are relatively minor on their own, phantom inventory cases compound fast. It’s a major uphill battle for store managers who don’t know where to direct their efforts. They have hundreds or thousands of SKUs to manage, and they can’t spend every single day checking every single shelf to find those tiny problems.

Why is phantom inventory such a headache for retailers?

Most retail stores only do full physical inventory counts once or twice a year. They look at the store from top to bottom and see how many they actually have of each unit, but these counts won't really fix the problem. They’re far too infrequent and error-prone to catch phantom inventory issues in a timely manner.

When errors go unnoticed for extended periods, it disrupts replenishment processes and creates unnecessary out-of-stock situations. Out-of-stocks lead to ongoing lost sales and negative shopping experiences for customers who can’t find the products they want. In fact, 2-4% of a retailer’s loss sales comes from phantom inventory.

To add insult to injury, phantom inventory creates an incomplete picture of customer demand that skews future demand forecasts and planning decisions. Ultimately, phantom inventory has long been a perpetual problem that hurts profitability.

How can retailers solve the problem?

Some retailers have tried using planogramming software or inventory scanning solutions to tackle phantom inventory. But since SKU assortments and store layouts vary across locations, these options haven’t been effective.

At Invent Analytics, we’re helping our clients take a whole new approach with AI. We use probabilistic forecasting to detect when something should be selling but is not for every single SKU-location combination. Then, we send store managers weekly alerts highlighting each suspected case of phantom inventory for their location. Managers get these alerts right through a smartphone app, so there is no complicated new system to learn.

Managers can take these highlights, go right to the issue, fix it, and then order more inventory as needed. We also track recurring issues, so managers can put proactive measures in place to prevent reoccurring problems. Our solution is quick and easy to roll out across a retailer’s store locations to solve the phantom inventory problem on a wide scale and ongoing basis.

Overall, we handle the heavy lifting behind the scenes, so retail store managers have everything they need to tackle phantom inventory and protect profitability — right at their fingertips.